According to recent trend of GWP hiking, which are impacted or contributed by both cement & concrete nowadays, the applications of smart construction materials help to reduce the same & enhancement to achieve the sustainable construction way.

What is the Durability & Sustainability of the concrete structures?

Durability & Sustainability: Durability & Sustainability both are similar mechanical properties of hardened concrete, if durability increases sustainability also increase & vice versa also. But High-performance concrete durability and sustainability both are require in higher side aspect to achieve its both durable and sustainable condition as per meets the target require by structural designs. Apart from this, high strength concrete does not mean it is will be more durable as compared to conventional concrete, rather high-performance concrete should always perform as more durable. Sustainability of concrete structure such majorly depends on the durability properties of concrete but periodically maintenance work can also enhance the both durability and sustainability properties of the concrete. Also, it has been proved that within timely maintenance or concrete repairable work done, the durability and sustainability will enhance & and it will affect the service life of concrete properties which will also increase as well as by reducing the deterioration of top surface of the concrete panel or slabs.

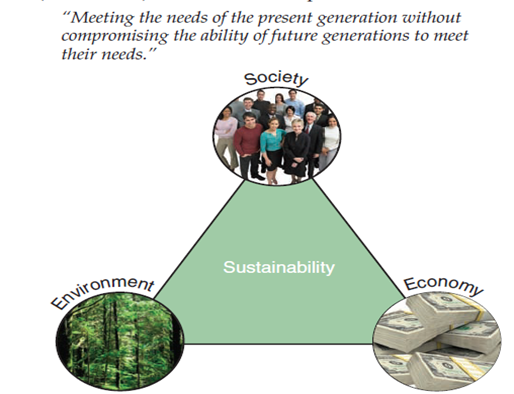

Sustainability of the concrete structures can depends upon the three factors, one is Economical way to execution, second is Environmental way to reduce the CO2 emission along with max. application of SCMs and third is Societal way to get the right decision prior to execution, if all the three achieve in a concrete structures or sections we can say that, its sustainable concrete, of course durability of the concrete should also be meets as per the SPEC. or contract based performance.

Smart Construction Materials- also known as intelligent, adaptive, or responsive materials—are engineered to sense, react, and adapt to changes in their environment without external control. Unlike traditional materials, they do not just passively endure stress or degradation—they actively respond to it & due to these, by the helps of the smart construction materials will can significantly achieve the both durability & sustainability of the concrete.

The following listed materials are to be considered, as smart construction materials-

1. AAC block- to reduce the carbon emissions & easy to construction.

2. GFRC bars to replace the traditional TMT- by light weight & more tensile strength capacity.

3. The application of cementitious materials- SCMs helps to reduce the clinker & carbon emissions as well as enhanced the concrete properties as compared to OPC alone.

4. Low Carbon biners- helps to reduce the GWP form concrete production.

5. Recycled or reused Agg. – helps to enhance the circular economy & enhanced the usages of materials.

6. Innovation chemical /additives/admixtures – ease to placement & enhancement both fresh & hardened concrete properties.

7. Innovative cements like LC3, PLC, Composite Cement- helps to modify the concrete properties & reduce the kg of CO2 eq./ton of cements.

8. M-Sand application- The rising demand for M-Sand (manufactured sand) is driven by a convergence of environmental, technical, and economic factors. Easy to conveyance & local sourcing it is the one of the most choice of selection as a fine agg. where, river sands are not available or not enough available in bulk qty for concreting works, here M-Sand is the best option in terms of both price & local sourcing.

9. Nano-materials like graphene, CNT, CNF, colloidal silica- Nano-materials, which are further enhanced the mechanical properties of the hardened concrete & more durable as compared to traditional concrete, also used as great repairing materials for concrete works.

✅ 1. AAC Blocks (Autoclaved Aerated Concrete)-

- Considered as smart materials: ✔️ Highly accurate.

- Why:

- Made with fly ash, lime, cement, and aluminium powder—often incorporating industrial by-products.

- Lightweight, thermally insulating, and reduces dead load.

- Lower embodied carbon than traditional clay bricks or dense concrete blocks.

- Ease of construction due to larger block size and workability.

✅ 2. GFRC Bars (Glass Fiber Reinforced Concrete)-

- Considered as smart materials: ⚠️ Partially accurate, but still not demanding may be less aware or not choice able till now in the market as comparison to TMT bars.

- Why:

- GFRC is typically used in panels, cladding, and architectural elements, not as direct replacements for TMT bars.

- Glass fiber reinforced polymers (GFRP) or carbon fiber composites are more appropriate analogues for replacing steel reinforcement.

- These alternatives offer corrosion resistance, high tensile strength, and light weight, but require careful design due to different failure modes and bond characteristics.

✅ 3. SCMs (Supplementary Cementitious Materials)-

- Considered as smart materials: ✔️ Spot on/highly demanding materials now, important part of the decarbonisation from concrete.

- Why:

- SCMs like fly ash, GGBFS, silica fume, calcined clay, metakaolin reduce clinker content and enhance durability, by reducing permeability of the concrete.

- Improve chloride resistance, sulphate resistance, and long-term strength & enhance the durability factor.

- Key to low-carbon concrete strategies and marine durability.

✅ 4. Low-Carbon Binders-

- Considered as smart materials: ✔️ Technically sound or highly essential to achieve net zero commitment, main part of the used as decarbonisation lever.

- Why:

- Includes geopolymers, alkali-activated materials, LC3, and blended cements.

- Can reduce GWP (Global Warming Potential) by 30–50% compared to OPC2.

- Often paired with carbon capture, optimized mix designs, and digital modelling for performance prediction.

✅ 5. Recycled or Reused Aggregates-

- Considered as smart materials: ✔️ Valid and increasingly adopted to reuse the concrete agg. through the C & D wastage, municipality wastage, pavement dismantling & returned or rejected concrete, also used as decarbonisation lever.

- Why:

- Supports circular economy and waste valorisation.

- Recycled concrete aggregates (RCA) retain ~85% of compressive strength.

- Challenges include higher water demand, variable quality, and need for pre-treatment.

✅ 6. Innovative Chemicals / Additives / Admixtures-

- Considered as smart materials: ✔️ Absolutely.

- Why:

- Includes superplasticizers, viscosity modifiers, shrinkage reducers, crack healing agents, and nano-silica, colloidal silica, water-proofing admixtures, pumping aid admixtures

- Enhance workability, setting control, durability, and mechanical performance.

- Crucial for high-performance concrete, self-consolidating mixes (SCC), and for the extreme environments.

✅ 7. Innovative Cements (LC3, PLC, Composite Cement)-

- Considered as smart materials: ✔️ Technically robust, used as decarbonisation lever.

- Why:

- LC3 (Limestone Calcined Clay Cement): Reduces CO₂ emissions by up to 40%, improves durability, and uses abundant materials.

- PLC (Portland Limestone Cement): Incorporates up to 15% limestone, reducing clinker demand.

- Composite cements: Blend multiple SCMs for tailored performance and sustainability.

✅8. M-Sand Application-

- Considered as smart materials: ✔️ Technically robust, M-Sand (Manufactured Sand) is increasingly being recognized as a smart construction material due to its engineered properties, sustainability benefits, and adaptability to modern construction demands.

- Why:

- Engineered Consistency- Controlled gradation and particle shape (typically cubical) improve packing density and reduce voids.

- Performance Optimization- Tailored for specific applications: concrete, plastering, masonry, etc.

- Sustainability & Environmental Intelligence- Reduces dependency on river sand, curbing ecological degradation and illegal mining & often produced near construction sites, minimizing transportation emissions.

- Digital Compatibility- M-Sand’s consistent properties make it ideal for digital mix design tools, BIM integration, and AI-based optimization in smart construction workflows.

✅9. Nano-materials-

- Nano Silica hydro gel, colloidal silica are the smart construction materials used into the construction & repairing works, also graphene, CNF & CNT & nano-silica, nano calcined clay are the most game changer materials considerable.

- The application of nano materials is also to be part of the smart construction materials, as its shape the innovative construction works & enhanced the mechanical properties as well as increase the service life of the concrete, as compared to traditional OPC based systems.

🔍 Summary Table-

| Material Type | Sustainability Benefit | Technical Note |

| AAC Blocks | Low carbon, thermal insulation | Excellent for non-load-bearing walls |

| GFRC Bars | Lightweight, corrosion-resistant | Better suited as panels; GFRP better for bars |

| SCMs | Reduces clinker, enhances durability | Essential for marine and aggressive environments |

| Low-Carbon Binders | Major GWP reduction, through the less carbon emission from concrete | Includes LC3, geopolymers, blended systems |

| Recycled Aggregates | Circular economy, enhanced the waste reduction through the re-usages | Needs quality control and mix adjustments |

| Innovative Admixtures | Enhances fresh/hardened properties | Key for placement ease and durability |

| Nano-materials applications | Enhances fresh/hardened properties of concrete, known as nano-enhanced concrete | Increase the service life & used as most successful repairing materials |

| M-Sand applications | Enhanced the engineered consistency with sustainable benefits for construction works | Reduces dependency on river sand & right blending with ultrafine SCMs will improve the overall concrete performance |

| LC3 / PLC / Composite Cements-innovative cements | CO₂ reduction, tailored performance | Validated by global research and field trials |

Conclusion- Hence, the applications of the smart construction materials in the industrial works, it will impact or enhance on both durability & sustainability of the designed concrete structures, as stated above the impact-ness of the smart materials & to avoid or reduce the carbon emission & embodied energy, which will further assist to part of the decarbonisation from the construction works.