Venus is constantly innovating to meet the diverse needs of the construction industry. We have recently expanded our product portfolio, introducing the Venus Placing Boom, with models VPB 33S-3R and VPB 36P-4R, engineered to provide efficient concrete placement in both confined areas and large open spaces.

Q. How is Venus Techno Equipment positioned in the competitive landscape of concrete, asphalt, and road equipment manufacturing, both domestically and globally?

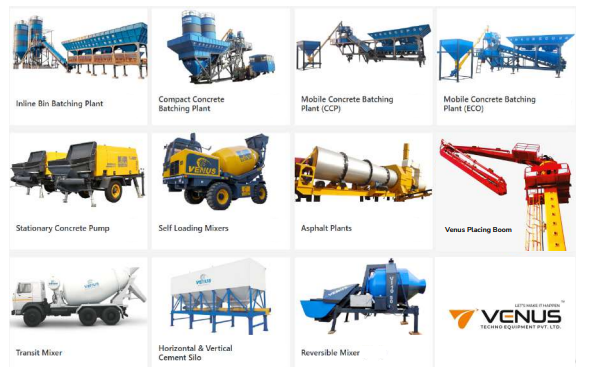

Venus Techno Equipment Pvt. Ltd. is positioned as a key player in the construction equipment industry, providing high-performance and innovative solutions for both the domestic and global markets. We specialize in self-loading concrete mixers, concrete pumps, batching plants, asphalt plants, and placing booms, tower cranes all designed to meet the evolving needs of contractors and infrastructure developers.

With a strong emphasis on continuous innovation and sustainable practices, Venus has become synonymous with quality, reliability, and engineering excellence. Our products are engineered to perform under challenging conditions, ensuring high productivity and operational efficiency. Additionally, our focus on local manufacturing, with our state-of-the-art Motap production unit in Mehsana, Gujarat, ensures that we are not only meeting domestic demand but also strengthening our global competitiveness.

Q. What are the core innovations driving Venus Techno Equipment’s growth and competitive edge?

Venus Techno Equipment is driven by innovation at every step. Our self-loading concrete mixers are engineered for higher productivity and fuel efficiency, catering to a wide range of applications. The Venus Placing Boom with fully hydraulic foldable arms is another testament to our innovation, designed to facilitate concrete placement in both congested sites and sprawling project areas. This product enhances operational efficiency and safety, making it ideal for challenging job sites.

Additionally, our asphalt batch mix plants and batching plants are designed to provide reliable and efficient solutions for road construction and urban infrastructure projects. With advanced IoT-enabled equipment and automation, we are continuously improving our machines to ensure superior operational efficiency and enhanced customer experiences.

Q. How is Venus Techno Equipment contributing to India’s infrastructure development, and what role do sustainability practices play in this?

Venus Techno Equipment is proud to be a key partner in India’s infrastructure development. Our products are integral to road construction, urbanization, and the development of smart cities. Through our Bharat Stage V-compliant equipment, we are playing an essential role in helping India transition to cleaner, more sustainable construction practices.

Our commitment to sustainability is reflected in our energy-efficient manufacturing processes, the eco-friendly design of our machines, and our adherence to global environmental standards. Venus follows responsible business operations that prioritize long-term solutions, ensuring that contractors have access to fuel-efficient, reliable, and durable machinery that contributes to environmentally responsible development.

Q. What new product developments and expansions can customers expect from Venus Techno Equipment?

Venus is constantly innovating to meet the diverse needs of the construction industry. We have recently expanded our product portfolio, introducing the Venus Placing Boom, with models VPB 33S-3R and VPB 36P-4R, engineered to provide efficient concrete placement in both confined areas and large open spaces. In addition, we’ve introduced Asphalt Batch mix plants with capacities of 120, 140, and 160 TPH , Tower Crane with model H5211A2-5, designed for high-output asphalt road-building projects.

Our self-loading concrete mixers are also available in multiple capacities, such as 2.6, 3.2, 4.5, and 4.8 cu.m/hr, to cater to a wide range of project requirements. These developments align with our philosophy of thinking ahead, engineering ahead, and delivering products that not only meet but exceed the expectations of the industry.

Q. What is Venus Techno Equipment’s strategy for global growth and international market expansion?

Venus Techno Equipment is rapidly expanding its global footprint, with a strategic focus on key markets in Asia, Africa, and the Middle East. We are strengthening our export capabilities and forming strategic alliances to increase our presence in these high-growth regions.

By focusing on local innovation and global excellence, we are integrating advanced technologies into our machines to ensure they meet the needs of contractors worldwide.

Q. How is Venus Techno Equipment addressing the challenges of stricter environmental regulations and emissions standards?

Venus Techno Equipment is at the forefront of compliance with Bharat Stage V norms, which align India with global emission standards. These norms push the industry toward producing cleaner, more fuel-efficient machines that reduce environmental impact. As part of this effort, we are investing in the development of energy-efficient machinery. We believe that transitioning to Stage V-compliant machines can be a significant challenge for contractors, which is why we are collaborating with financing institutions and government programs to make these machines more accessible through low-interest financing and government incentives.

Q. What are Venus Techno Equipment’s key strengths in the highly competitive construction equipment market?

Venus’s success in the highly competitive construction equipment market lies in its focus on quality, reliability, and customer satisfaction. With an extensive network of 25 sales and service offices across India and neighboring countries, and a team of over 200 trained engineers and technicians, we are able to offer robust after-sales support and value-driven solutions.

Moreover, we follow lean manufacturing practices and emphasize value engineering across our entire product range, ensuring that we provide machines that are not only high-performing but also cost-effective. We also focus on training our operators and service teams, including on-site training to ensure proper maintenance and operational efficiency.